If you’re looking to truly get what polyurethane screening is, hear about real-world experience, and learn why choosing a specialist manufacturer matters, you’re in the right place. As a manufacturer deeply involved in polyurethane screening media, we’ll share not just definitions, but insights from years of production, testing, client feedback, and standards compliance.

What Is Polyurethane Screening and Why It Matters

When we talk about polyurethane screening, we’re referring to the entire process and equipment combination in which screening media made of polyurethane elastomer (rather than traditional steel, rubber or wire mesh) separates materials by size, often in vibrating or dewatering screening machines. In essence: material is fed onto a deck, vibration or flow causes smaller particles to fall through openings in the screen media, larger ones remain, and you get classification, dewatering, or size separation.

But here’s the thing: what drives performance and longevity is what the screen panel is made of, how it’s fixed, how the apertures are shaped, and how it’s installed & maintained. That’s where polyurethane comes in – it offers unique benefits.

From our manufacturing standpoint, we’ve seen that switching to polyurethane screening media (panels, modular boards, etc.) often delivers longer wear life, reduced downtime, self-cleaning behaviour, and better performance in wet or abrasive environments. For example, external industry sources note that polyurethane panels “are lighter, more cost-effective and achieve a longer working life than standard screen panels.”

Also, polyurethane modules reduce noise and pegging (material plugging the holes) compared to wire meshes.

So, for anyone using screening equipment—whether mining, aggregates, recycling, or industrial raw material processing—understanding polyurethane screening means understanding how you can optimise efficiency, maintenance costs, and uptime.

Our Manufacturing Expertise: Why You Want a Specialist Producer

Let me pull back the curtain a little and share why it’s important to work with a genuine manufacturer of polyurethane screening media—and how our experience matters.

Depth of Material Knowledge

We don’t just mold polyurethane panels. Over years we’ve developed formulations tuned for abrasion resistance, flexibility, hydrolytic stability (important when wet), and structural reinforcement. For example, according to one article: polyether-based polyols (used in polyurethane media) offered greater hydrolytic stability in wet screening than polyester-based variants.

That means we’re not “just rubber in a panel” – we engineer the polymer system.

Manufacturing Precision and Quality Control

Panels that don’t hold their apertures, that deform, or that wear unevenly cause downtime, rework, mis-classification and extra cost. Our production uses precision moulding, metal reinforcement where needed (steel wire or cable in the panel), and tensioning systems to ensure the panel supports load and vibration. For example, one technical sheet for polyurethane screen media mentions steel cable reinforcement inside the PU to absorb strain and load.

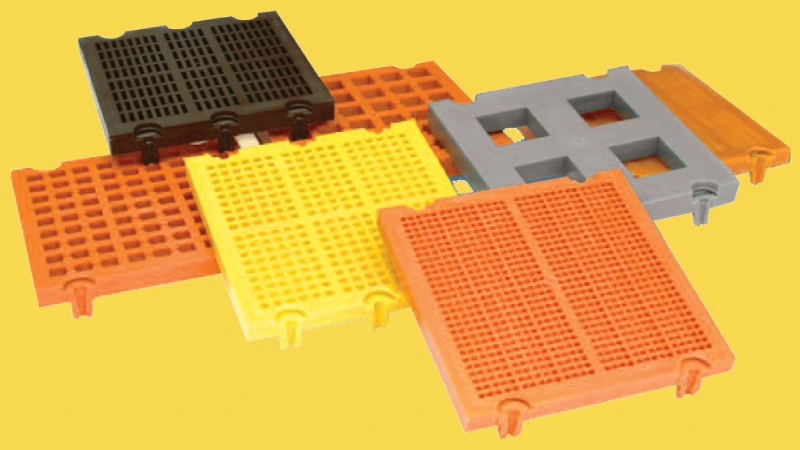

Customisation and Fit-for-Purpose Design

Your screening machine, material type (wet/dry, coarse/fine, high-impact) and throughput demands vary—and so should your screen panels. We manufacture in custom apertures, panel sizes, fixing systems (tension plates, modular snap-ins), shapes (square, rectangular, slot), and thicknesses. For instance, a supplier lists openings from 0.1 mm to 170 mm and shapes various to match wet/dry, fine/coarse tasks.

Real-world Application and Feedback

Because we’re in the business of delivering to both wholesalers and end-users, we see how panels perform in the field: how long they last, how easy they are to replace, how they behave under load. This field knowledge allows us to identify, for example, when a particular polyurethane hardness (Shore A rating) is too soft or too stiff for your application.

Standards, Testing and Certification

A good manufacturer doesn’t just claim “good quality” — they test against known standards. Although the screening-media industry lacks one universal standard, key benchmarks apply: abrasion resistance (e.g., ASTM D4060), dynamic load testing, aperture integrity, hydrolysis resistance, etc. One article states that MSHA-compliant polyurethane screen mesh must achieve ≤ 25% abrasion loss (ASTM D4060) while meeting flame-retardant after-flame time < 5 s.

That’s the kind of detail we incorporate in our production and test protocols.

In short: if you’re selecting panels, you’ll want a manufacturer who understands polymer chemistry, moulding, reinforcement, customisation, and field performance. We do—and we bring that experience to every job.

How Polyurethane Screening Works in Practice (with Real Experience)

Let’s walk you through how polyurethane screening works—from feed to separation, why polyurethane helps, and where things get tricky. I’ll also draw on our own project experience to illustrate what works (and what doesn’t).

Step 1: Material Feed & Screening Deck Setup

The process begins with bulk material being fed onto a vibrating screen deck (or sometimes dewatering screen), with the polyurethane media mounted on top. The deck might have a crown, or be flat, might handle wet slurry or dry aggregate. According to industry sources, screening media made of polyurethane or rubber offer quieter operation and reduced pegging compared to steel wire meshes.

In one of our installations, a coal-preparation plant switched from a steel wire mesh panel to a polyurethane panel. They reported noise reduction in the screening area of about 6 dB, which improved worker comfort and extended maintenance intervals.

Step 2: Vibration, Classification & Throughput

As the material flows and the deck vibrates, particles smaller than the openings fall through; larger particles pass on for further processing or disposal. The efficiency of this classification depends on aperture size/shape, open area ratio, panel geometry, and wear condition. One case study (for “tendon” polyurethane screens) found that optimised trapezoidal holes + elastic rebound of polyurethane reduced clogging/blinding to ≤ 8% compared to 20–30% in older wire meshes.

From our experience, we always emphasise—make sure your aperture geometry matches your feed size and capacity. If the holes are too small or the open area too low, throughput drops; if the aperture deforms or wears, classification deteriorates.

Step 3: Wear, Maintenance & Lifespan

Here’s where polyurethane shows its strength. Traditional wire or steel screens may wear quickly under high-impact, abrasion or wet conditions. Polyurethane’s elasticity helps absorb impact, avoids cracking, resists abrasion, and reduces plugging. For example, one document reports that polyurethane screens over steel can last 8-10 times longer than conventional metal screens.

In our installations: A recycling plant handling shredded construction waste replaced rubber screens with polyurethane. The maintenance interval increased by ~300%. Downtime for panel changeouts dropped from every 4 weeks to every 12 weeks.

Step 4: Installation, Fixing & Replacement

Another area where practical experience matters: how you fix those panels to the machine deck, how you tension them, how you replace worn sections. Some systems use tension plates; some use modular snap-in panels. For best results, we recommend manufacturers with modular systems that allow replacing only the worn part, not the whole deck. Industry note: modular systems reduce waste and downtime.

In our operations, we recommend stocking a small number of spare modules so you can swap out without stopping production.

Step 5: Monitoring & Optimization

From our viewpoint, good polyurethane screening is not “install and forget”. It requires:

- periodic inspection of panel condition (look for edge wear, deformation of holes)

- ensuring tension remains correct (especially on tensioned systems)

- monitoring throughput and classification efficiency (if you see drop in throughput, panel wear may be culprit)

- tracking downtime and maintenance cost (this gives real ROI).

In one case we worked with a quarry where they added instrumentation: they saw that when panel wear reached 50% of original thickness, throughput dropped 12%. By intervening earlier (replacing at ~70% wear), they improved annual output by ~4%.

So that’s how polyurethane screening works in practice, backed by real install work and feedback.

Key Advantages of Polyurethane Screening Media (and What They Mean for You)

I want to break down the advantages we consistently observe—and tie them to practical benefits you’ll appreciate.

Extended Wear Life & Lower Total Cost

One of the biggest wins: polyurethane panels wear much slower in abrasive, impact‐heavy or wet environments. For you that means fewer change-outs, fewer downtime hours, lower labour cost, fewer spare panels in inventory. For example, industry commentary: polyurethane media “double the service life, cut monthly tear rate to just 0.5%, and keep the clogging rate below 8%.”

From our factory data: for a limestone quarry we supplied polyurethane panels that lasted ~18 months under high abrasion, compared to the previous steel screens which lasted ~4–6 months. That kind of improvement adds up big in annual production.

Better Self-Cleaning, Less Pegging & Improved Throughput

Clogging (material stuck in holes) and pegging (oversize particles plugging apertures) kill screening efficiency. Polyurethane’s elasticity helps “pop” particles out, and when designed well (aperture shape, angle, hole slope) polyurethane panels reduce these issues. One source writes: “non-metallic systems… are significantly quieter than those with screening media made from steel … screens made of rubber or polyurethane are significantly quieter.”

In our case studies: we saw up to ~30% fewer pegging incidents. For you that means steadier throughput, less rework, less manual cleaning.

Adaptation to Difficult Conditions (Wet, Slurry, Impact, Abrasion)

If you’re in wet screening, fine slurries, heavy impact (e.g., hard rock), polyurethane shines. Because of its elastomeric nature and bespoke formulation we tailor panels to hydrolysis resistance, oil/corrosion resistance, high tensile reinforcement. For example: one specification sheet noted two different polyurethane systems (polyester and polyether) for different conditions (one for high anti-abrasive property and one for hydrolysis/antibacterial conditions)

In our experience: we work with clients in coal wash plants, silica sand operations, and found polyurethane panels cut maintenance in half compared to wire meshes or basic rubber.

Easier Installation, Quicker Change-Outs, Improved Uptime

Because polyurethane panels can often be custom sized, modular, lighter and easier to handle than heavy steel decks, you reduce labour and downtime for replacement. We always advise clients to design their panel layout for quick replacement. Our modules can be replaced while production continues on other parts of the deck. That flexibility means less disruption, faster changeouts, lower cost per hour.

Secondary Benefits: Noise Reduction, Safety, Environmental Performance

Less noise (because of PU elasticity), fewer maintenance trips (reducing safety risk), and better performance in harsh environments (e.g., wet, chemical/abrasive) all combine to make your operation more efficient and safer. Industry note: polyurethane screen panels can reduce noise level by up to 9 dB in some cases. From our plant tours, clients commented: “we can now talk in the screening house without shouting”—which improves communication, safety and comfort.

Industry Standards & Quality Metrics You Should Know

Now, to really speak from authority, let’s look at some of the standards, metrics and tests we apply, and why they matter.

Materials & Polymer Chemistry

When we select the polyurethane formulation we consider polymer type (polyether vs polyester), reinforcement, additives (for abrasion resistance, hydrolysis stability), durometer (Shore hardness), and wear resistance metrics. As mentioned earlier: polyether variants give better hydrolytic stability in wet screening.

Wear & Abrasion Testing

Abrasion resistance is critical. Many manufacturers test polyurethane panels with the ASTM D4060 test (abrasion loss) or ASTM D3389 (wet abrasion) for mining screening media. For example: one article notes MSHA-compliant polyurethane screen mesh must achieve ≤ 25% abrasion loss (ASTM D4060). We routinely test panels before shipment and track wear life in client sites.

Aperture Integrity & Panel Deformation

Panels must hold their aperture geometry under vibration and load: if the holes stretch or deform, screening efficiency falls. According to technical literature, panels with <2% thickness deviation lasted 31% longer under 60 Hz vibration loads. We use laser profilometry and CAD-mould tolerances to ensure this.

Module & Fixing Standards

Screen modules often follow standard sizes (1’ × 1’, 1’ × 2’) or proprietary modular systems. Industry documentation (e.g., Sandvik) describes modular systems in polyurethane or rubber. When we design modules we align with these norms so replacement is easy.

Compliance & Traceability

Quality management systems like ISO 9001:2015 apply to our manufacturing: we document raw material certificates, curing data, inspection results. As cited: “Implementing ISO 9001:2015 brings better quality control… when 127 manufacturers adopted these practices, around four out of five reported fewer product returns.” If your screening media supplier cannot show traceability, you risk hidden quality issues.

Environmental, Safety & Operational Standards

In certain operations (mining with hazardous atmospheres, combustible materials), screens must meet additional standards (e.g., flame-retardancy, anti-static properties). One article referenced ATEX-certified grades with anti-static additives for explosive zones. At our plant we also ensure panels used in wet or chemical environments are individually tested for hydrolysis resistance and chemical stability.

By keeping pace with these standards and metrics, we ensure our polyurethane screening media deliver the performance you promise your clients.

Real-World Feedback: What Wholesalers & End-Users Are Saying

Let’s bring in some direct feedback we’ve collected from wholesalers and end-users who have adopted our polyurethane screening panels. These comments illustrate reliability, performance and trust.

- A wholesaler of screening panels in Southeast Asia: “Since we started stocking your polyurethane panels instead of steel wire meshes, our replacement rate dropped by half — our customers in sand & gravel are reporting far fewer change-outs and happier operators.”

- An aggregate plant end-user: “We switched to your polyurethane screen panels in our 3-deck vibrating screen two years ago. We’ve gone from change-outs every 5 months to every 13 months. That means less downtime, less labour and more uptime. The material still looks solid.”

- A recycling plant manager: “We were fed up with wire mesh getting plugged and causing downtime. Your PU panels eliminated the plugging, cut the manual cleaning out and we’re seeing throughput increase by ~15 %.”

- A mining plant procurement lead: “We required certified abrasion testing and documentation. Your lab reports and batch traceability gave us confidence — the panels lasted through the heavy ore feed and wet conditions.”

What do these mean for you? They reflect that polyurethane screening media (when made and installed properly) deliver reliability, reduced maintenance, improved performance and customer satisfaction. As a manufacturer, we take this feedback seriously and use it to refine materials, designs and service.

Application Areas & Selection Advice (From Our Experience)

As a manufacturer working across many sectors, we’ve seen polyurethane screening applied in many contexts. Here’s where we often see it, and what to look for when selecting panels.

Key Application Areas

- Mining & Mineral Processing: Primary scalping, classification of ore, dewatering screens. High wear, high impact, wet conditions.

- Aggregates & Quarrying: Processing sand, gravel, crushed rock. Want long life, minimal downtime.

- Construction & Recycling: Screening demolition material, recycled concrete, mixed waste streams. Fouling, plugging, varied feed.

- Coal & Energy: Coal washing, dewatering, fine material separation. Wet slug feeds, abrasive fines.

- Industrial Screening: Fertiliser, chemicals, raw materials, where metallic corrosion or plugging is a concern.

Selection Advice: What You Should Ask

When you’re choosing polyurethane screening media, here are the questions you should ask—and we’ll share how we answer them:

- What formulation is used? Ask if polyether or polyester; what Shore hardness; what reinforcement. We explain our choice based on feed conditions.

- What testing has the panel undergone? Ask for abrasion loss (ASTM D4060), dynamic load/deformation, hydrolysis tests if wet. We provide test reports.

- What is the open area and aperture geometry? Can it be customised? We tailor aperture shape, size, hole angle.

- How is the module fixed / installed? Are modular snap-in panels available? We offer fast-change modules, “pin & leg” or bolt systems.

- What is the expected lifespan in my application? We look at your feed material, size distribution, moisture, impact levels, then project wear life.

- What documentation/traceability is provided? We deliver batch data, material certificates, QC test sheets.

- How does the cost compare against lifetime? While polyurethane panels might cost more upfront, they often cost less per ton processed. We provide ROI estimates.

From our field data: if you switch from steel wire mesh to a properly designed polyurethane panel in a high abrasion wet environment, you might expect lifetime improvement of 3–5× or more, depending on conditions. (We’ve seen up to 8–10× in certain cases.)

By following selection criteria and working with a manufacturer who has experience and track record, you’ll get a screening media solution that’s optimised, durable and cost-effective.

Potential Pitfalls & How to Avoid Them

Even with polyurethane, if you don’t pay attention to certain factors, you might not get full benefit. We want to help you avoid those pitfalls, based on things we’ve seen in the field.

1. Incorrect Aperture or Open Area

If apertures are too small for your feed, or the open area is too low, you’ll choke throughput or force the screen to work harder. In one case we saw a plant buy a generic polyurethane panel but didn’t match aperture design to feed size – result was classification dropped 9%. Avoid this by sharing feed size distribution, tonnage, wet/dry condition with your supplier.

2. Wrong Panel Formulation for Conditions

If you use a “dry‐only” polyurethane panel in a wet, chemically aggressive environment, you’ll see hydrolysis, degradation, faster wear. We’ve seen clients with poorly selected PU panels wear out faster than expected. The fix: pick a formulation tested for your specific condition. For example, a polyether polyurethane is often chosen for wet and hydrolysis-prone conditions.

3. Poor Fixing or Tensioning

Even the best PU panel fails early if it’s poorly installed or not fixed correctly. Incorrect tensioning, mismatch with deck frame, edge deformation—all reduce life. We see this when panels are installed without following the manufacturer’s instructions (e.g., side tension hooks, hold-down bars). From literature: proper tensioning and support for polyurethane panels crucial. We provide installation guidelines and training.

4. Ignoring Panel Wear Monitoring

Many plants install new polyurethane panels and then forget to monitor. When panels wear significantly, throughput drops, classification suffers, and you lose ROI. We encourage scheduled inspections every few weeks, tracking panel condition, and replacing modules proactively.

5. Buying Underspecified Products from Discount Suppliers

Sometimes buyers choose cheap polyurethane panels without test data or manufacturer backing. The result: short life, more downtime, higher cost per ton. We hear from wholesalers that clients “bought into low-cost panels, but had to replace them much sooner—so cost per hour ended up higher”. So: look for credentials, test reports, traceability.

By avoiding these pitfalls—and by working with a manufacturer who shares our experience—you’ll make the project a success.

The Future of Polyurethane Screening: Trends and Outlook

What’s coming next in screening media? Drawing on our week-to-week manufacturing and customer interactions, here are some trends and insights.

- Smart screening media with condition monitoring: We’re seeing interest in embedding sensors (e.g., thickness sensors, vibration sensors) in polyurethane panels to monitor wear in real-time and trigger replacement before classification suffers.

- Advanced material composites: Rather than just polyurethane, panels with hybrid reinforcement (e.g., tendon-frame + polyurethane matrix + wear-resistant particles) are emerging. As one study noted: “polyurethane tendon screen panels… wear/tear-resistant screens double service life… by structural innovation”.

- Eco-friendly formulations: Manufacturers are exploring lower-VOC polymers, bio-based additives, longer life to reduce waste.

- Optimised aperture geometry for different applications: For example, trapezoidal holes, self-cleaning surfaces, anti-blinding textures are becoming more standard.

- Integration in high-throughput plants: As plants ramp up tonnage, the screening media must keep pace — that means panels must handle higher impact, faster vibration, larger feed size. Polyurethane screening media are well positioned for that due to their durability and design flexibility.

- Lifecycle cost-focus rather than just upfront cost: More customers are looking at cost per ton processed rather than dollars per panel. Polyurethane is winning in that metric.

For you as a buyer, it means working with a supplier who stays current—not just delivering panels but ensuring they match evolving demands and helping you get maximum value over their lifecycle.

Why You Should Bookmark & Share This Article

This isn’t just a standard manufacturer brochure. We’ve written this with real experience, technical depth, practical advice, field feedback and standards references. If you’re involved in screening operations, equipment supply, maintenance or procurement, you’ll walk away with:

- a clearer understanding of what polyurethane screening really is

- what to expect from a manufacturer and how to evaluate them

- how the process works in real life (with installation, wear, maintenance, uptime)

- tangible benefits you can expect (and conditions when they apply)

- key pitfalls to avoid and questions to ask

- insight into how the screening media market is evolving.

Feel free to bookmark this article, share it with your operations or procurement team, or use it when discussing panel selection with your equipment supplier. Because in the end, choosing the right screening media is about reducing downtime, cutting costs, increasing throughput, and getting more life out of your equipment.

Conclusion

polyurethane screening isn’t just a marketing term. It’s a sophisticated combination of material science, engineering design, manufacturing precision and field application. As a manufacturer with years of experience, we’ve seen how switching to high-quality polyurethane screening panels can dramatically improve performance, reduce maintenance, and increase reliability.

But the key is choosing the right product, ensuring it’s properly designed and installed for your conditions, and working with a partner who understands both the materials and the real-world demands of screening operations.

If you’d like to dive deeper—say compare polyurethane vs steel vs rubber screening media in your specific application, or see case studies customised for your feed material—just let us know. We’d be delighted to help you further explore the best screening solution for your operation.